107 Series 3-Phase Inverter Duty Gearmotors and Drives

1 /2Páginas

107 Series 3-Phase Inverter Duty Gearmotors and Drives

1 /2Páginas

Extractos del catálogo

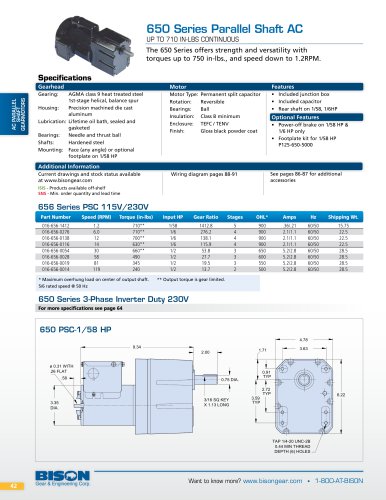

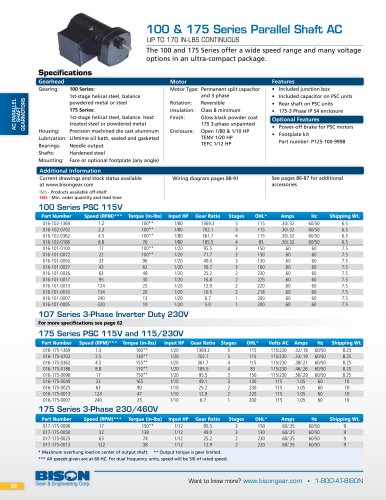

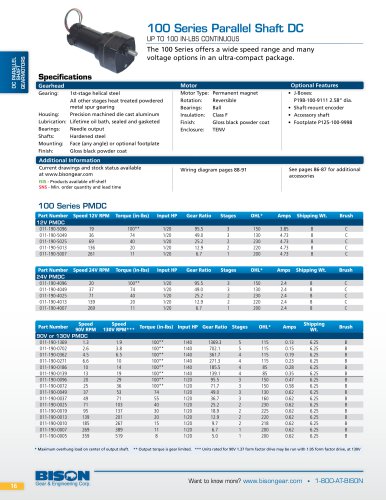

Variable Frequency Drives Isolated PWM AC NEMA 4X Bison’s Variable Frequency Drives feature a lightweight, plastic NEMA 4X enclosure, an isolated front end, minimum speed adjustment potentiometer, output voltage doubling, DC injection braking, and automatic or manual restart when power is restored. 4 1 4.0 0-120 Hz NEMA 4X 0 1/6 to 1 7.200 [ 183 ] 0.188 [5] 5 6 0 170-543-0004 115 or 230V Single Phase Gear & Engineering Corp. OFF REV Horsepower Output Output Rating 230V Current Frequency Configuration 8 9 Input Voltage FWD 2 3 7 Part Number POWER 1 Variable Frequency AC Drive NEMA 4X 5.625 [143] SPEED 6.350 [161] • • Isolated inputs: Accepts floating or grounded signals 0-10VDC, 0-5VDC or 4-20 mA • ADJUSTABLE SPEED REVERSING AC MOTOR CONTROL NEMA 4x enclosure: Compact, easy to mount, black plastic enclosure User adjustable calibration pots: Minimum speed, maximum speed, current limit, acceleration, deceleration, slip compensation, boost, zero set, brake current, and brake time. 0.89 [22.6] 5.625 [143] POWER FWD OFF • Diagnostic LED’s: Power, fault, and torque limit • Stopping modes: DC injection braking or coast (jumper schedule) • Adjustable 4 to 16 kHz switching frequency; Quiet motor operation or reduced electrical noise REV 2 3 8 9 1 1 BOTTOM PLATE 0.73 [18.5] CONDUIT HOLES 2 PLACES 0 0 SPEED 4.56 [116] 6.350 [161] Quick Disconnect terminal block: Allows up to 200% torque to overcome intermittent peak loads • 7.200 [ 183 ] 0.188 [5] 5 6 7 • 4 Additional features: Auto or manual restart after low input voltage fault (jumper selectable), line fusing, enable and direction inputs ADJUSTABLE SPEED REVERSING AC MOTOR CONTROL 2.12 [53.8] 0.89 [22.6] 2.20 [55.9] 3.40 [86.4] ALL DIMENSIONS IN INCHES [MILLIMETERS] 0.73 [18.5] CONDUIT HOLES 2 PLACES BOTTOM PLATE PWM AC Chassis The cost-conscious and compact chassis design of Bison VFD Chassis Drives maintain the industry standard for mounting hole location and the coded LEDs make it easy to visually determine the drive status. With it’s compact design and application flexibility, this is an excellent choice for most AC applications. 4.56 [116] 2.12 [53.8] 2.20 Variable Frequency AC Chassis Drive [55.9] 3.40 [86.4] Part Number Input Voltage ALL DIMENSIONS IN INCHES [MILLIMETERS] 170-503-0002 115 or 230V Single Phase H 1/6 to 1/2 2.4A 0-120 Hz Chassis U V TB501 TH501 DECEL TQ C501 ACCEL 3.70 [94] 2 .7 2 [6 9 ] J501 Easy to calibrate & set up: On-board trimmer pot adjustments for boost, maximum speed, acceleration and deceleration Torque “foldback” feature: Allows up to 200% torque for short periods to overcome intermittent peak loads, then reduces the torque to a preset safe level • 16kHz switching frequency, with option to change between 4 and 16 kHz in the field: A high switching frequency results in quiet motor operation. Adjustments to a lower frequency if desired can be done in the field W L2 E2 E1 S1 S2 S3 D • 3.80 [97] Compact size: 4.3” x 3.7” easy to-mount in small spaces with industry standard mounting hole pattern • 0.96 [24] TQ JMP501 107 Horsepower Output Output Rating Current Frequency Configuration • 4.30 [109] 2.12 [54] 107 Series 3-Phase Inverter Duty Gearmotors and Drives C5 02 115V J501 IC502 C510 230V 0 .9 7 [ 2 5 ] L1 TOTAL HEIGHT (TOP OF CAP TO BOTTOM OF CHASSIS) ALL DIMENSIONS IN INCHES [MILLIMETERS] VF D0 1 -D2 30 AC 2.56 [65.0] VFD02 - D2 3 0AC 3.02 [76.7] Gear & Engineering Corp. 3850 Ohio Avenue • St. Charles, IL 60174 Ph: 800-AT-BISON • Int’l. Ph: 1-630-377-4327 Fax: 630-377-6777 • Email: info@bisongear.com www.bisongear.com www.bisongear.com 1-800-AT-BISON

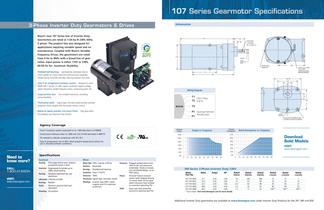

Abrir la página 1 del catálogo107 Series Gearmotor Specifications 3-Phase Inverter Duty Gearmotors & Drives Schematics Bison’s new 107 Series line of Inverter Duty Gearmotors are rated at 1/20 hp @ 230V, 60Hz, 3 phase. The product line was designed for applications requiring variable speed and no maintenance. Coupled with Bison’s Variable Frequency Drives, the gearmotors are rated from 6 Hz to 90Hz with a broad line of gear ratios. Input power is either 115V or 230V, 60/50 Hz for maximum flexibility. Shielded ball bearings I (permanently lubricated, electric motor grade) on motor maximize overhung load capability....

Abrir la página 2 del catálogoTodos los catálogos y folletos técnicos BISON

- Bison® Gearmtors

6 Páginas

- PRODUCT PORTFOLIO

4 Páginas

- Nautilair® Combustion Blowers

4 Páginas

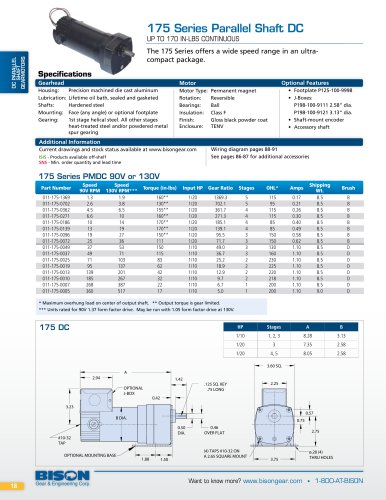

- 175 Series Parallel Shaft DC

1 Página

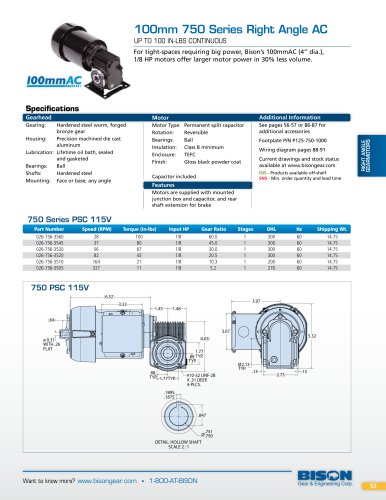

- 750 Series Right Angle AC

1 Página

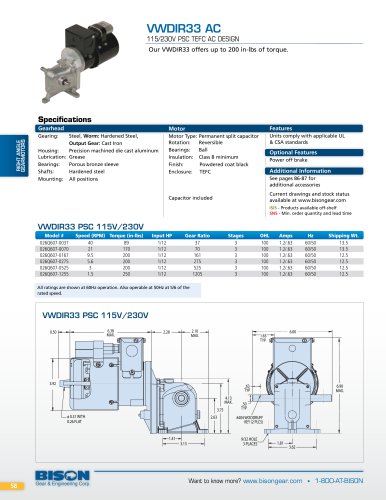

- VWDIR33

1 Página

- 746 Series

1 Página

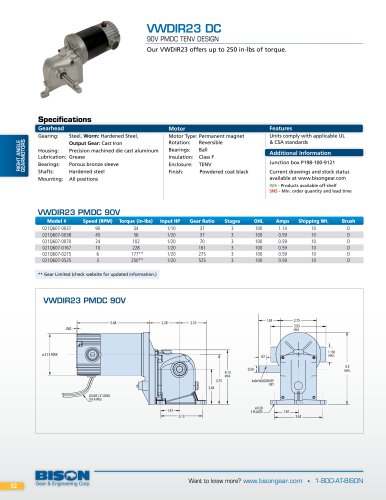

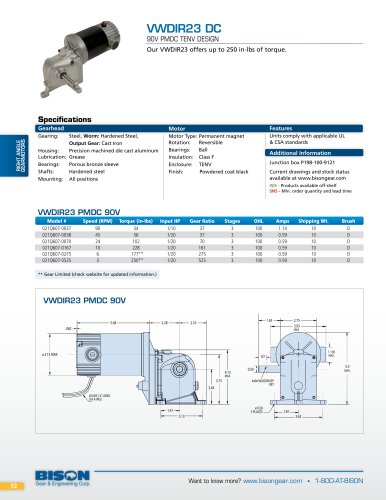

- VWDIR23 DC

1 Página

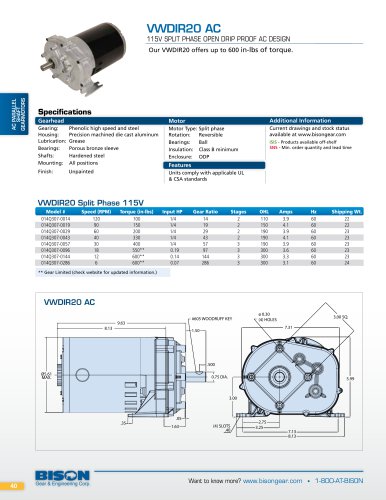

- VWDIR20

1 Página

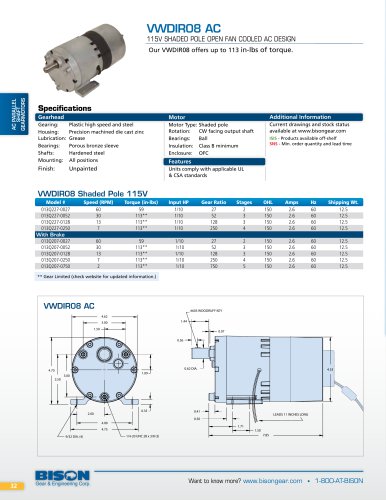

- VWDIR08

1 Página

- VWDIR14

1 Página

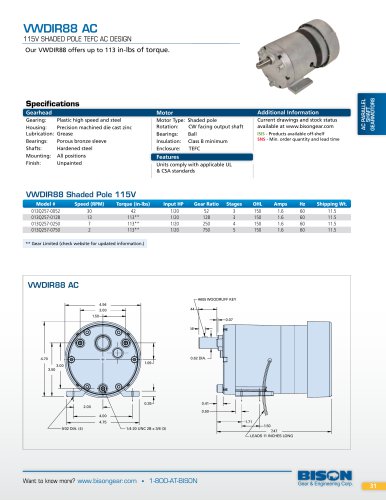

- VWDIR88

1 Página

- 055 series

2 Páginas

- Integral Horsepower

8 Páginas

- PowerSTAR

20 Páginas

- We Make Your Products Go

100 Páginas

- Powerstar X63

2 Páginas

- Powerstar X62

2 Páginas

- Powerstar X53

2 Páginas

- Powerstar X52

2 Páginas

- Powerstar X43

2 Páginas

- Integral horsepower Product Catalog

56 Páginas

- Sanitary Washdown Product Catalog

8 Páginas

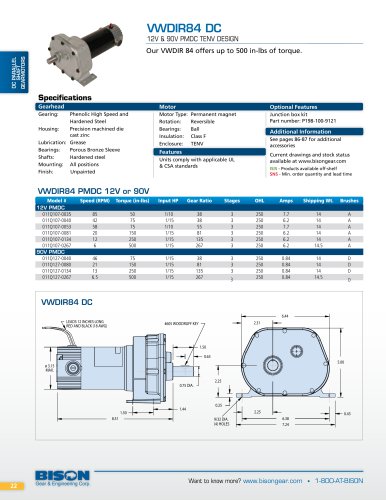

- VWDIR 84 DC

1 Página

- VWDIR 23 DC

1 Página

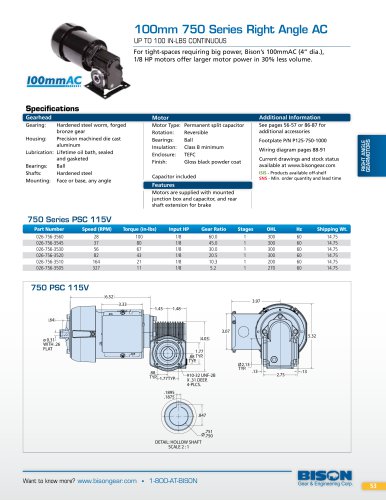

- 100mm 750 Series Right Angle AC

1 Página

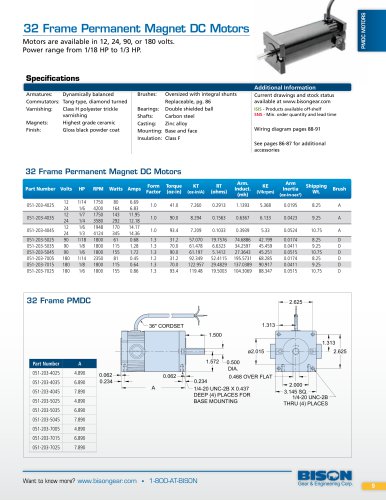

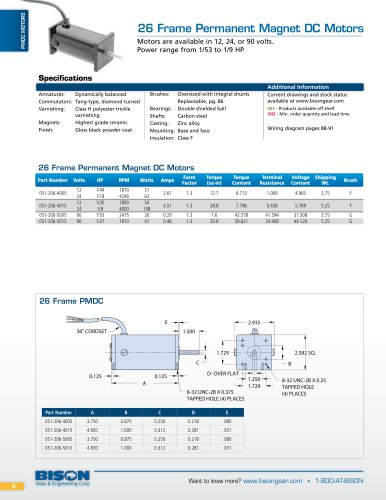

- PMDC Product Line Catalog

20 Páginas

- 712 DC Series Gearmotor Guide

8 Páginas

- 650 Series Parallel Shaft AC

2 Páginas

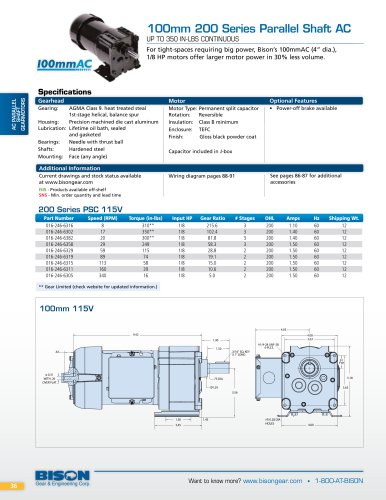

- 200 series Parallel shaft AC

3 Páginas

- 480 Series Parallel Shaft AC

1 Página

- 100 & 175 Series Parallel Shaft AC

2 Páginas

- Brushless DC Guide

12 Páginas

- Bison Full Product Line

2 Páginas

- Hollow Shaft Offset Gearmotors

2 Páginas

- PowerSTAR®

16 Páginas

- SANIMotor

2 Páginas

- DRIVES AC & DC Variable Speed Drives

2 Páginas

- PowerSTAR 725 Series Brochure

4 Páginas

- AUTONOMotorTM

2 Páginas

- ServoNOW

2 Páginas

- 750 Series Gearmotor

2 Páginas

- 200 Series Gearmotor

2 Páginas

- Custom AC Motors 34 and 49 Frame

2 Páginas

- AC Si DC Right Angle Gearmotors

2 Páginas

- Motor Mounted Speed Control

2 Páginas

- Full Product Line Overview

8 Páginas

- Offset Parallel Shaft Gearmotor

1 Página

- Bison gear general catalog

100 Páginas

Catálogos archivados

- AC and DC Drives

2 Páginas

- Hollow Shaft Right Angle Gearmotors

2 Páginas

- The Bison Difference

2 Páginas

- Custom AC Motors

2 Páginas

- Hollow Shaft Offset Gearmotors

2 Páginas