Extractos del catálogo

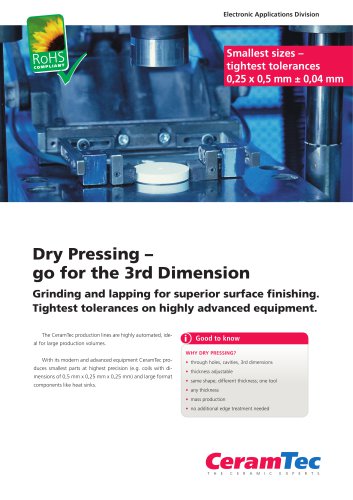

SPK-CUTTING TOOL DIVISION ADDED VALUE TECHNOLOGY APPLICATION NEW MILLING CUTTER GENERATION High Speed Roughing and Finishing

Abrir la página 1 del catálogo

TECHNOLOGY APPLICATION ADDED VALUE Achieving the optimal machining of a workpiece is no longer solely dependent on the cutting process. Increasing technological and economical challenges require highly efficient machining processes. To this end, we have developed the programme “SPK+ - The Productivity Experts” with the formula: tool + technology + application = increased productivity with lower costs. It has already been shown that the formula means a boost in productivity for our customers in many specific applications. In the future, we will draw attention to this by placing a...

Abrir la página 2 del catálogo

E-Mail: info@spk-tools.com

Abrir la página 3 del catálogo

PMK - High Speed Roughing and Finishing The PMK face milling cutter system is ideally suited for the rough milling and finishing of GJL (grey cast iron) and GJS (ductile cast iron) materials. These milling cutters work with an approach angle of 88°. FINISHING OPERATIONS USING PMK In order to attain outstanding surface qualities during finishing, the PMK series has been fitted with insert seatings that can be set in the Z-direction. This setting option allows users to pre-set the speciallydeveloped broad finishing inserts in the µm range. The inserts in the fixed insert seating take over the...

Abrir la página 4 del catálogo

Machining Example TOOL LIFE QUANTITY INCREASED UP TO 133% FOR FINISH MILLING OF A GEAR-BOX ADDED VALUE REQUIREMENTS: - INCREASE TOOL LI FE QUANTITY - REDUCE MACHINI NG TIME CONDITIONS: - DRY MACHINING CUTTING MATERI AL MIX SiAlON SL808 AN D CBN WBN115 SPK ENGINEERING FOR INCREASING EFFICIENCY THROUGH - DEFINITION MILLING STRATEGY - DEFINITION OF CUTTING DATA Finish Milling of a Gear-Box Made of GJS500 Competitor SPK-Cutting Tools Cutting Material: Tungsten Carbide Miling Cutter: Machinig Time: Tool Life: E-Mail: info@spk-tools.com

Abrir la página 5 del catálogo

Machining Example TECHNOLOGY APPLICATION ADDED VALUE TOOL LIFE QUANTITY INCREASED UP TO 215% PRE-FINISHING OF A HYDRAULIC BLOCK REQUIREMENTS: FE - INCREASE TOOL LI QUANTITY NG TIME - REDUCE MACHINI CONDITIONS: - SURFACE QUALITY AL MIX CUTTING MATERI D SiAlON SL808 AN CBN WBN115 SPK ENGINEERING FOR INCREASING EFFICIENCY THROUGH - DEFINITION OF MILLING STRATEGY - DEFINITION OF CUTTING DATA Pre-Finishing of a Hydraulic Block Made of GJS400 Competitor Cutting Material: Tungsten Carbide Milling Cutter: Machining Time: Tool Life: SPK-Cutting Tools E-Mail: info@spk-tools.com

Abrir la página 6 del catálogo

Fon:+49-7163-166-239 Fax:+49-7163-166-388 E-Mail: info@spk-tools.com Web: www.spk-tools.com • ceramtec.com

Abrir la página 7 del catálogo

Face Milling Cutters PEK ... 88R-AM Axial rake angle a Recommended application Radial rake angle r depending on Ø -6° to -9° Mounting dimenion according to DIN 8030 WORKPIECE thin-walled E-Mail: info@spk-tools.com

Abrir la página 8 del catálogo

Face Milling Cutter PMK Axial rake angle a Radial rake angle r depending on Ø -6° to -9° Mounting dimenion according to DIN 8030 WORKPIECE thin-walled t = 6 (5+1): totally 6 teeth, there of one tooth adjustable E-Mail: info@spk-tools.com

Abrir la página 9 del catálogo

PMKS Face Milling Cutters - Coarse Pitch Axial rake angle a Radial rake angle r depending on Ø: -6° to -9° Recommended application GJL (grey cast iron) Mounting dimenion according to DIN 8030 For thin-walled and unstable parts WORKPIECE thin-walled GJS (ductile cast iron) Example: t = 6 (5+1): totally 6 teeth, there of one tooth adjustable E-Mail: info@spk-tools.com

Abrir la página 10 del catálogo

Inserts for PMK and PMKS Milling Cutters E-Mail: info@spk-tools.com

Abrir la página 11 del catálogo

Face Milling Cutters PFK ... 88R-AM Axial rake angle a Recommended application Radial rake angle r depending on Ø -6° to -9° Mounting dimension according to DIN 8030 WORKPIECE thin-walled For thin-walled and unstable parts E-Mail: info@spk-tools.com

Abrir la página 12 del catálogo

Inserts for PFK ... 88R-AM Milling Cutters SNCN 0904ZZ T INSERT SNCN 0904ZZ T SNCN 0904ZZ T SNCN 1204ZN T SNCN 1204ZN T SNCN 1204ZN TZN T SNCN 12 04 445° 45° 5° SNCN 1204ZZ T SNCN 12 04 T SNCN 1204ZZ T ZZ2.4 SNCN 1204ZZ T SNCN 1204ZZ T 445° 45° 5° SNER 1204ZN E - HC SNER 1204ZN EZNHC- HC SNER 12 04 - E SNER 1204ZN E - HC E-Mail: info@spk-tools.com

Abrir la página 13 del catálogo

Face Milling Cutters PFK ... 75R-AM Axial rake angle a Recommended application Radial rake angle r depending on Ø -6° to -9° Mounting dimension according to DIN 8030 For thin-walled and unstable parts WORKPIECE thin-walled E-Mail: info@spk-tools.com

Abrir la página 14 del catálogo

Inserts for PFK... 75R-AM Milling Cutters E-Mail: info@spk-tools.com

Abrir la página 15 del catálogo

Face Milling Cutters PFK ... 45R-AM Axial rake angle a Recommended application Radial rake angle r depending on Ø -6° to -9° Mounting dimension according to DIN 8030 For thin-walled and unstable parts WORKPIECE thin-walled E-Mail: info@spk-tools.com

Abrir la página 16 del catálogo

Inserts for PFK ... 45R-AM Milling Cutters E-Mail: info@spk-tools.com

Abrir la página 17 del catálogo

Square Shoulder Milling Cutter PFK ... 90R-AM Axial rake angle a Recommended application Radial rake angle r depending on Ø -6° to -9° Mounting dimension according to DIN 8030 WORKPIECE thin-walled For thin-walled and unstable parts E-Mail: info@spk-tools.com

Abrir la página 18 del catálogo

Inserts for PFK ... 90R-AM Milling Cutters TNCN 1604 04 .. T TNCN 16 . . T TNCN 1604 . . T TNCN 1604 PN T TNCN 1604 04 PN T TNCN 16 PN T E-Mail: info@spk-tools.com

Abrir la página 19 del catálogo

PFL - New Generation for High Speed Machining with Positive Geometrie The PFL milling cutter family was especially designed for the highly-productive face milling of components made from GJL (grey cast iron) and GJS (ductile cast iron) with SiALON cutting materials. • PFL-OP: the milling cutter line for rough milling and finishing • PFL SP: this milling cutter series was designed for finishing and for medium rough milling operations with low axial forces. The PFL milling cutter family comprises two classic series with a positive geometry: PFL-OP This roughing and finishing specialist is...

Abrir la página 20 del catálogo

PFL-OP Face Milling Cutters Axial rake angle a GJL (grey cast iron) Mounting dimension according to DIN 8030 stable WORKPIECE thin-walled GJS (ductile cast iron) Radial rake angle: r Recommended application E-Mail: info@spk-tools.com

Abrir la página 21 del catálogoTodos los catálogos y folletos técnicos CERAMTEC

-

Lasering ? go for highest precision

2 Páginas

-

TOOLS FOR TURNING

188 Páginas

-

SYSTEM S3

56 Páginas

-

RAG

37 Páginas

-

HARD TURNING

60 Páginas

-

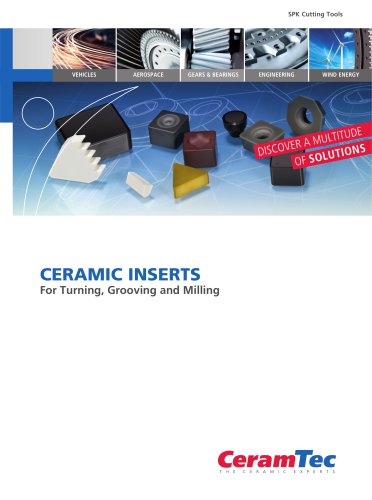

CERAMIC INSERTS

96 Páginas

-

PERLUCOR®A New Era In Transparency

8 Páginas

-

PERLUCOR® Transparent Ceramics

16 Páginas

-

Ceramic Materials

4 Páginas

-

Cyrol® ceramic bearing rollers

4 Páginas

-

SPK® PFK90-TN

132 Páginas

Catálogos archivados

-

SPK Tools for hard materials

112 Páginas

-

RAG Grooving with lateral movement

72 Páginas

-

Materials for gas ignition

2 Páginas

-

Advanced Ceramics in Piezo Applications

40 Páginas

-

BIOLOX®DUO - Ceramic Bipolar System

12 Páginas

-

Soldering Conditions for Actuators

2 Páginas

-

Rubalit® 708 HP ? High-Performance

2 Páginas

-

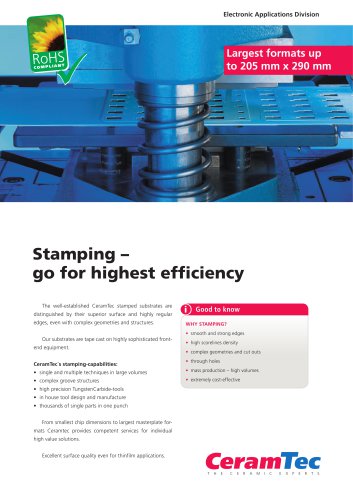

Stamping ? go for highest efficiency

2 Páginas

-

CeramCool® Substrates

2 Páginas

-

Tools for Turning

188 Páginas

-

EXACTLY TO YOUR SPECIFICATIONS.

6 Páginas

-

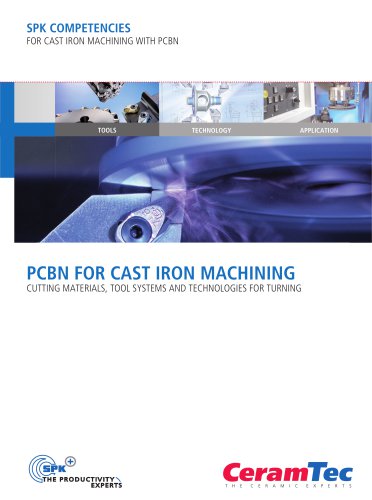

PcBn for cast iron Machining

24 Páginas

-

triduon thermo tames Temperature

16 Páginas

-

BIOLOX ? Ceramics for Hip Arthroplasty

16 Páginas

-

ALUTIT Aluminum Titanate

6 Páginas

-

ALOTEC

11 Páginas

-

Monolithic Multilayer Actuators

16 Páginas

-

PERLUCOR A New Era In Transparency

8 Páginas

-

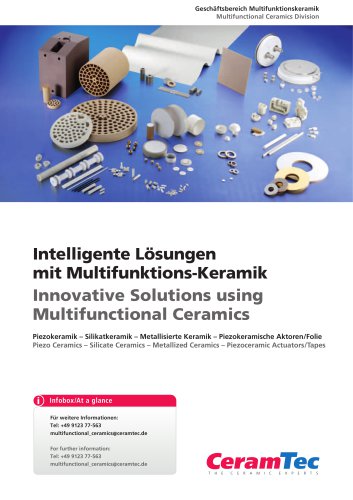

Multifunctional Ceramics Division

40 Páginas

-

SPK Tools for turning

340 Páginas

-

SPK Milling Tools

76 Páginas