Extractos del catálogo

Heatless Regenerative Desiccant Dryer

Abrir la página 1 del catálogo

Heatless Regenerative Desiccant Dryer iÉ~ÇáåÖ=íÜÉ=t~ó=áå=^áê=mìêáÑáÅ~íáçå Adsorption drying — Why? Compressed air is an important process and energy medium applied in almost all areas of industrial production. The atmospheric air taken in contains contaminants, dirt particles and humidity, i.e. water vapor, which condensates in compressed air pipes. This condensation can lead to considerable costs (corrosion, freezing). These costs can be avoided by using the applications of the Donaldson Ultrapac 2000 heatless desiccant dryer. This complete purification system includes a prefilter, dryer,...

Abrir la página 2 del catálogo

Heatless Regenerative Desiccant Dryer O Lower Shuttle Valve O Upper Shuttle Valve Dimensions & Specifications * Capacity rated in accordance with CAGI ADF 200 @ 100 psig, 100°F inlet, 100° ambient, and a PDP of -40°F. A pressure dew point of -100°F can be achieved at a capacity decrease of 30%. Ambient air temperature: 38°-125°F, inlet air temperature: 40-125°F, operating pressure: 60-225 psig. Standard power supply: 110V/60 Hz, other options available.

Abrir la página 3 del catálogo

Capacity Correction Factors The leading manufacturers of compressed air and gas equipment in North America are organized in the Compressed Air & Gas Institute (CAGI). As the premier industry organization, CAGI has developed standards to protect users of this equipment. ADF 200 is the current standard for desiccant compressed air dryers. ADF 200 specifies the dryers performance to be rated at 100°F inlet temperature, 100°F ambient temperature, and 100° psig system pressure. To adjust the dryer capacity from these “CAGI conditions” to your specific application, please use the correction...

Abrir la página 4 del catálogoTodos los catálogos y folletos técnicos DONALDSON

-

COMPRESSED AIR AND PROCESS FILTRATION

20 Páginas

-

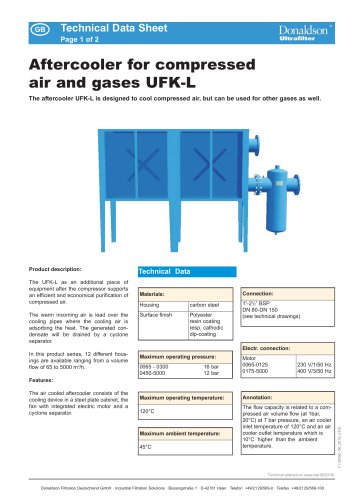

UFK-L Aftercoolers

2 Páginas

-

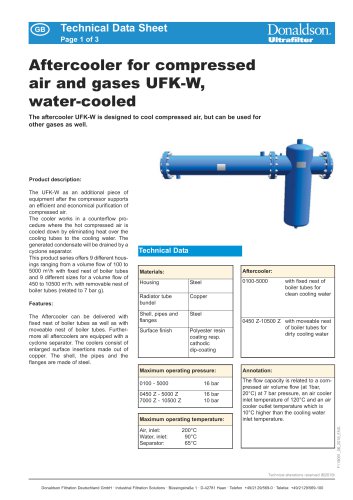

UFK-W Aftercoolers

3 Páginas

-

P-EGS

3 Páginas

-

CULINARY & PROCESS STEAM

8 Páginas

-

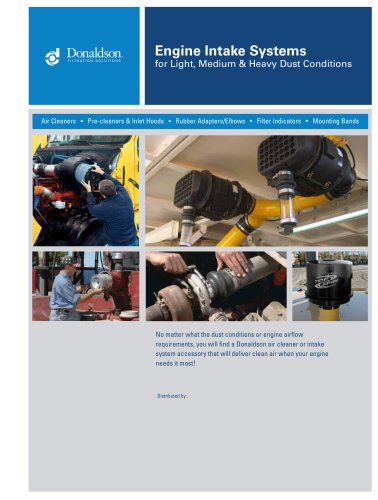

Air Intake Systems

8 Páginas

-

Clean DEF Solutions

4 Páginas

-

High Performance Filter Cartridges

2 Páginas

-

Clean Fuel & Lubricant

32 Páginas

-

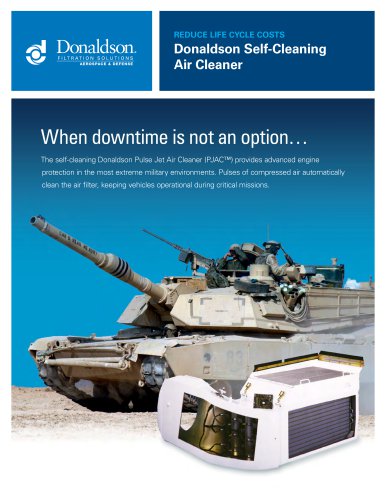

Donaldson Self-Cleaning Air Cleaner

4 Páginas

-

Exhaust System Solutions

2 Páginas

-

Pressure Control Systems

2 Páginas

-

Innovative Fuel Systems

2 Páginas

-

HEPA Filtration Facts

2 Páginas

-

AEROSPACE & DEFENSE

4 Páginas

-

PowerCore® G2 Filtration Technology

8 Páginas

-

pOWERCO RE® air cleaners

8 Páginas

-

Donaldson Strata™ Tubes

4 Páginas

-

PG-EG 0006 – 0192

6 Páginas

-

(P)-GS N

6 Páginas

-

Minerals Brochure

4 Páginas

-

Metals Brochure

4 Páginas

-

Industrial Filtration

10 Páginas

-

Pharma Industry - Tetratex

2 Páginas

-

Microfiltration

2 Páginas

-

Surface vs Depth Filtration Brochure

4 Páginas

-

Power Generation

8 Páginas

-

Vacuum Cleaner and Sweepers

4 Páginas

-

Hydraulic Filtration

320 Páginas

-

LDV FILTER KITS

4 Páginas

-

Engine Liquid Filtration

154 Páginas

-

Cabin Air Filtration

2 Páginas

-

ToriT®powercore®dusT collecTors

16 Páginas

-

PLEATED BAGS

3 Páginas

-

DALAMATIC ® DUST COLLECTORS

12 Páginas

-

HPK05

6 Páginas

-

Engine Intake Systems

171 Páginas

-

Ultrabev P-PF-BEV

4 Páginas

-

Capsule Filters

8 Páginas

-

Adsorbent Recirculation Filter (ARF)

2 Páginas

-

Filter Housing HD High Pressure

3 Páginas

-

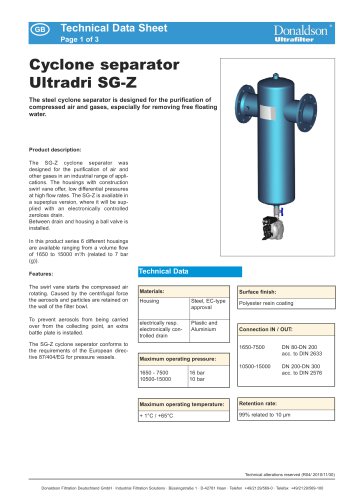

Cyclone separator Ultradri SG-Z

3 Páginas

-

Oilfreepac® 2000 Standard

3 Páginas

-

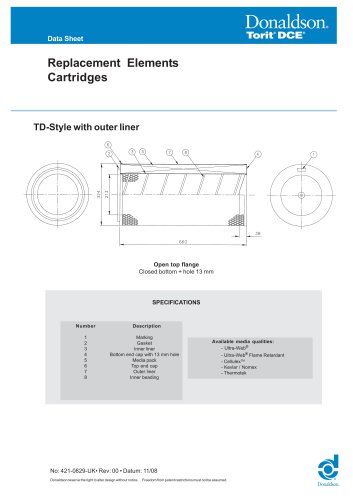

Replacement Elements Cartridges

2 Páginas

-

Clean Fuel Cart X011407

1 Páginas

-

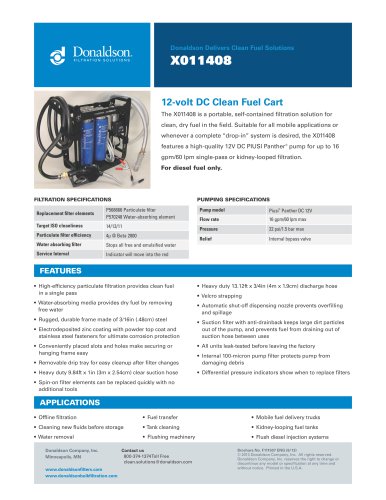

Clean Fuel Cart X011408

1 Páginas

-

Bulk ISO OEM Cleaniness Flyer

1 Páginas

-

Air Purification System (APS?)

4 Páginas

-

Leakage Detector DLD

2 Páginas

-

SG Standard Filter Housing

7 Páginas

-

Bulk Clean Diesel Filter Kits

2 Páginas

-

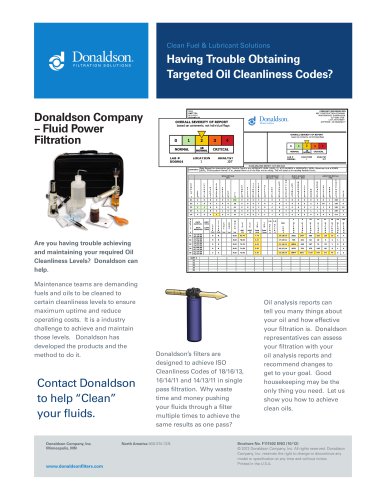

Bulk Oil Cleaniness Levels

1 Páginas

-

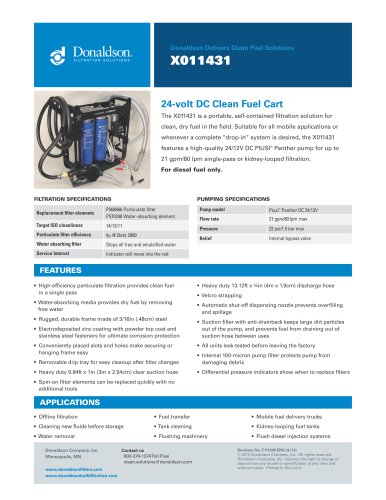

Clean Fuel Cart X011431

1 Páginas

-

Venting Product Overview

2 Páginas

-

Tetratex Pleatable Filter Media

2 Páginas

-

Vacuum Cleaners and Sweepers

4 Páginas

-

Chemicals Brochure

4 Páginas

-

DPF Thermal Regenerator IOM

16 Páginas

-

Adsorbent Breather Assembly

2 Páginas

-

Adsorbent Pouch Filter

2 Páginas

-

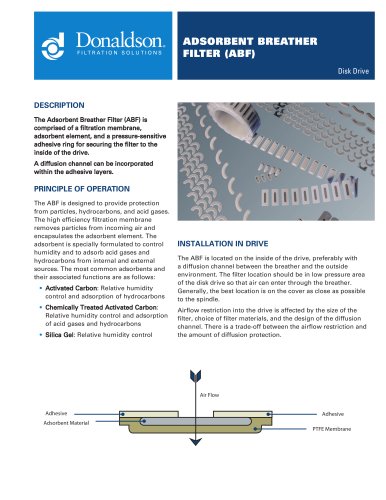

Adsorbent Breather Filter

2 Páginas

-

Bulk hP

4 Páginas

-

Bulk Fuel and Lube Filtration

4 Páginas

-

ULTRAPOREX SB

2 Páginas

-

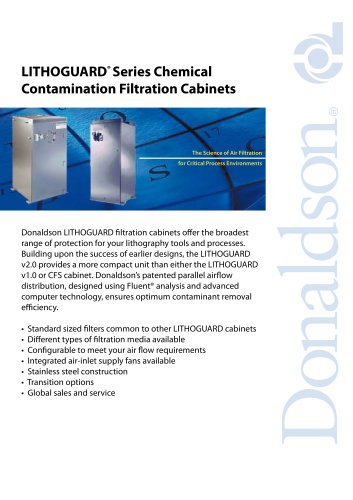

LITHOGUARD®

2 Páginas

-

BSMmax

2 Páginas

-

Valves & Solenoids

2 Páginas

-

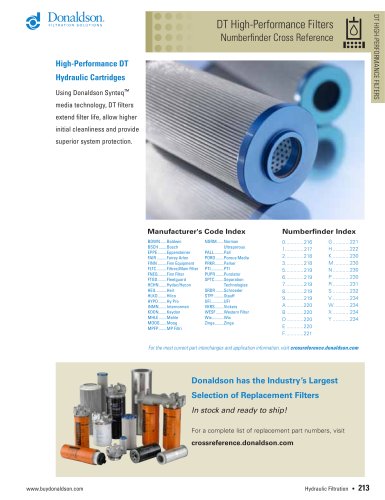

DT filter

22 Páginas

-

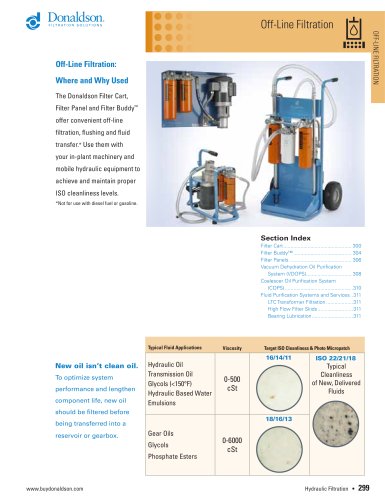

Off-Line Filtration

14 Páginas

-

Sight Glasses

1 Páginas

-

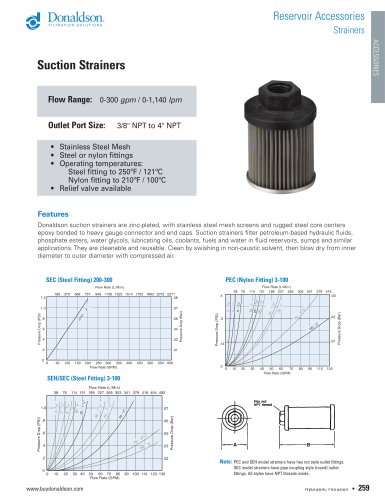

Strainers

4 Páginas

-

Valves

6 Páginas

-

Breathers

14 Páginas

-

TT15/30/60

2 Páginas

-

SP100/120

4 Páginas

-

Low Pressure Filters

64 Páginas

-

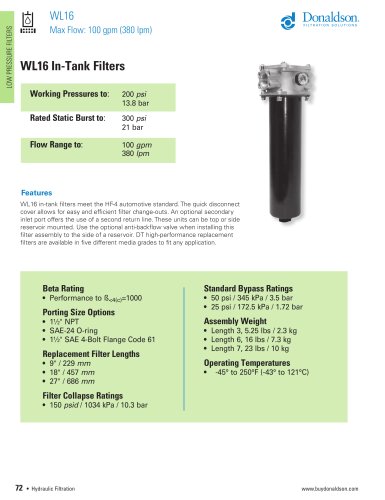

WL16

4 Páginas

-

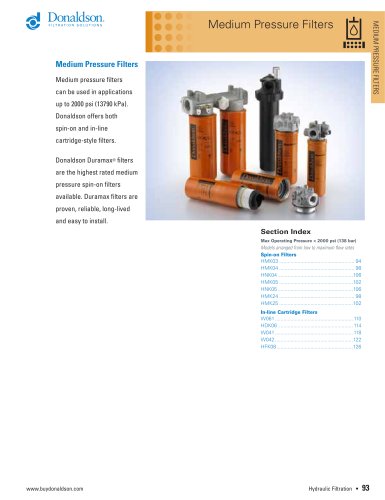

Medium Pressure Filters

38 Páginas

-

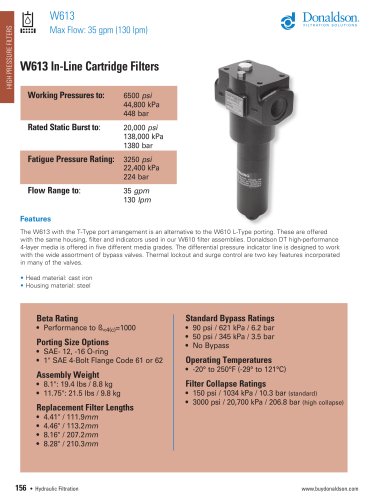

W613

4 Páginas

-

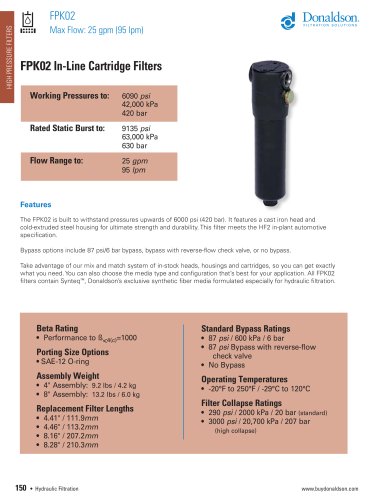

FPK02

6 Páginas

-

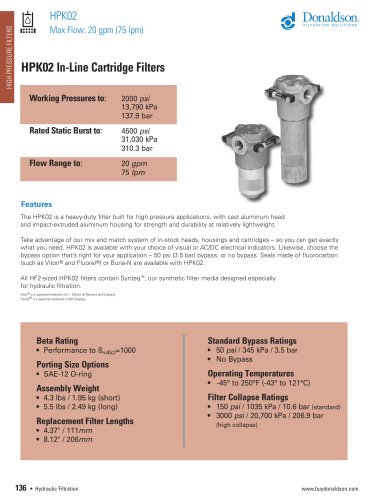

HPK02

4 Páginas

-

W610 In-Line Cartridge Filters

4 Páginas

-

High Pressure Filters

86 Páginas

-

Hydraulic Filtration Solutions

8 Páginas

-

panel filter

1 Páginas

-

GDX

4 Páginas

-

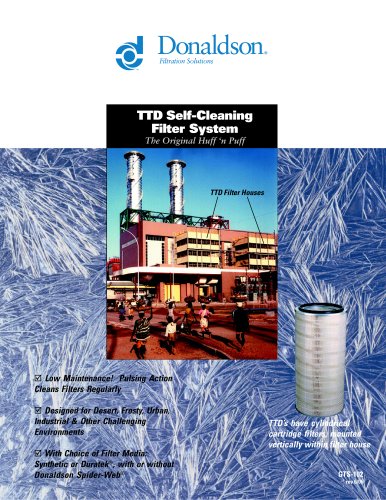

TTD Self-Cleaning Filter System

4 Páginas

-

DISK DRIVE SEALS

2 Páginas

-

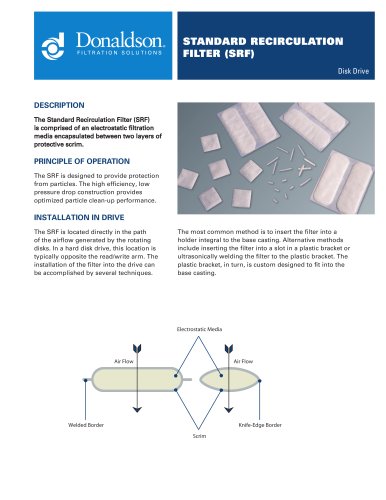

STANDARD RECIRCULATION FILTER (SRF)

2 Páginas

-

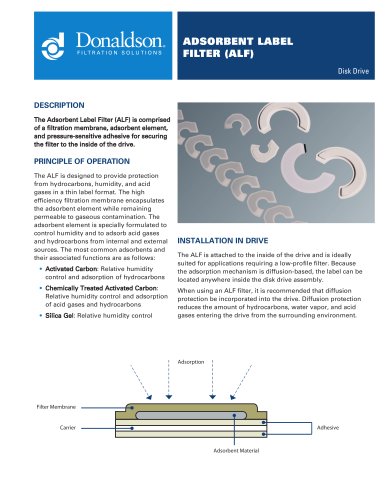

ADSORBENT LABEL FILTER (ALF)

2 Páginas

-

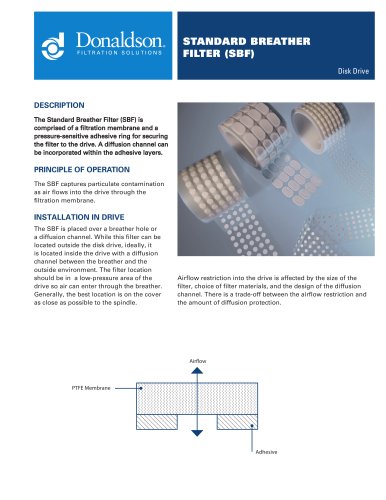

STANDARD BREATHER FILTER (SBF)

2 Páginas

-

Hydraulic Filtration

374 Páginas

-

Engine Liquid Filtration

132 Páginas

-

Oil/Water Separators

6 Páginas

-

THREE-STAGE FILTERS DF-THREE SERIES

4 Páginas

-

cyclone separator df-c series

2 Páginas

-

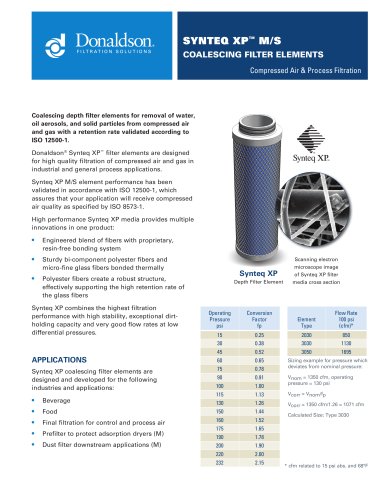

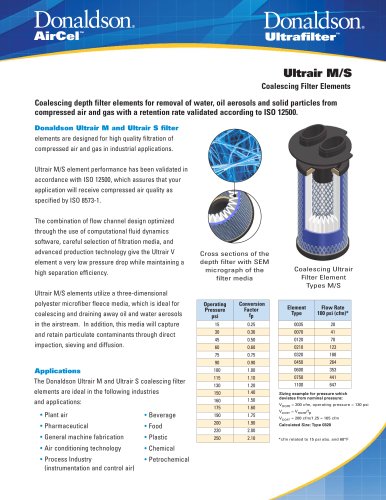

SYNTEQ XP M/S

2 Páginas

-

Synteq XP

4 Páginas

-

Ultrac? AK

2 Páginas

-

Ultrapoly? PE

2 Páginas

-

ULTRAC A

2 Páginas

-

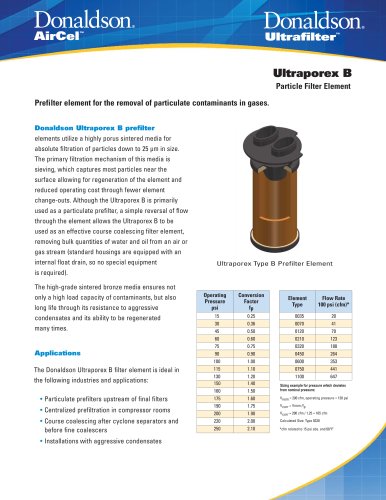

Ultraporex B Particle Filter Element

2 Páginas

-

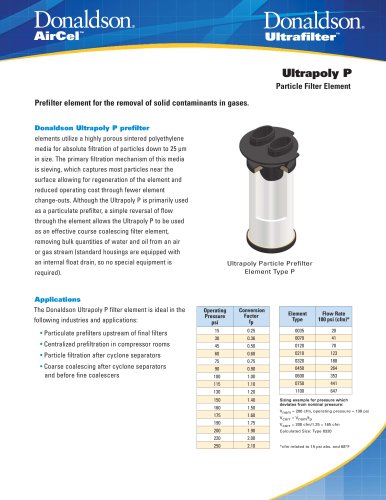

Ultrapoly P Particle Filter Element

2 Páginas

-

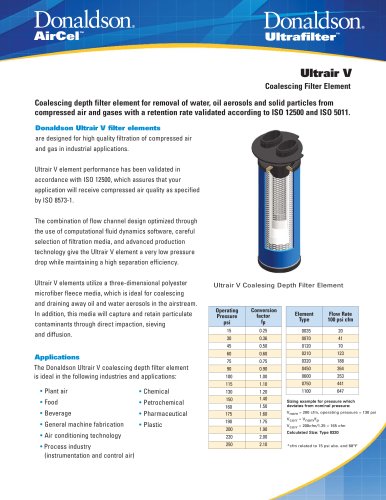

Ultrair V Coalescing Filter Element

2 Páginas

-

Dryer Package Filters

2 Páginas

-

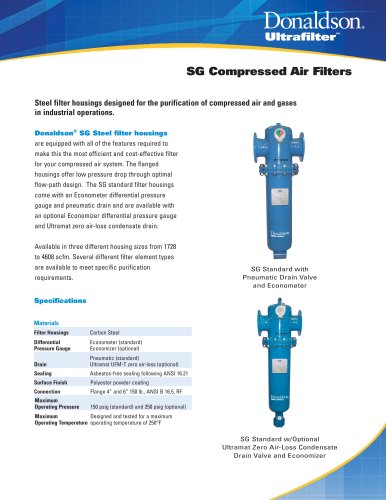

SG Compressed Air Filters

2 Páginas

-

AG Compressed Air Filters

2 Páginas

-

HD High Pressure Filter Housings

2 Páginas

-

AG/SH Industrial Filters Housings

8 Páginas

-

Rotary Valves

10 Páginas

-

Unimaster® Dust Collector

4 Páginas

-

Unicell Dust Collectors

6 Páginas

-

Downflo Dust Collectors

6 Páginas

Catálogos archivados

-

Sensor Vents

2 Páginas

-

Fluid Analysis

12 Páginas

-

Exhaust Product

186 Páginas

-

Compressed Air Dryer Brochure

8 Páginas