- Catálogos

- Rapid Granulator

- Rapid Series S : 10_20_300_400_500_60_80 & GranuMATIC

Rapid Series S : 10_20_300_400_500_60_80 & GranuMATIC

1 /50Páginas

Rapid Series S : 10_20_300_400_500_60_80 & GranuMATIC

1 /50Páginas

Extractos del catálogo

pieces can then be cut into uniform granules by the toothed cutting wheels. The crusher blades come in two sizes. An optional automatic reversing system is available that reverses the rotation of the rotor for a short while to clear any material obstruction. The granule size is uniform at 5 mm. The common backbone of all Rapid granulators is a cutterhouse incorporating rotating and fi xed knives together with screen with a hole diameter that determines the size of regrind. This has proved to be the best solution for virtually all the granulation applications we have encountered. However,...

Abrir la página 2 del catálogoAll dimensions in mm. The granulator can be opened easily without tools to give access to all com-ponents to facilitate granulator cleaning and maintenance. C 766 A 384 150 As waste feeds into the cutting wheels, the teeth cut the pieces cleanly into high-quality granules of uni- fotrm size. The reinforced teeth and powerful slow- speed cutting action easily slice through the hardest materials. 700 1372 522 B 510758 A B C 1022 290 610 220x1601034 410 685 340x160 1046 530 780 460x160 Cutterhouse opening, mm 223 241 343 241 464 ח 241Crusher blades 1 2 3 Motor, kW standard 0.75 1.8 1.8...

Abrir la página 3 del catálogoThe new Rapid 20 Series of granulators is ideal for the direct recycling of plastic waste and rejects primarily from injection moulding and blow moulding processes. No matter what your requirements, a standard model is available to suit your exact needs for capacities up to 190 kg/h. > The number of standard alternatives, like cutterhouse width, rotor confi guration, rotor speed, dis charge systems, etc., allow you to select the granulator best suited to your type of plastic waste, throughput vo lume, granule size and direct recycling require-ments. > The ability to select standardized...

Abrir la página 6 del catálogoThe confi guration of the rotor blades and low rotation speed combine to minimize energy consumption. > A consistently smooth and clean cutting action contri- butes to high quality regrind. Because of its bolted construc-tion, it is easy to remove and replace worn parts in the cut- terhouse. > The small granulator foot-print saves valuable fl oor-space and castors allow units to be moved easily to other locations as required. The tangential feed of the cut-terhouse reduces fl yback of waste and enables fi rm feed ing of lightweight material to increase grinding capacity. The constant...

Abrir la página 7 del catálogoNon-soundproofed models are just one of the many standard alternatives of the Rapid 20 Series. Easy cleaning and maintenance Cleaning machine parts in response to a change in plastic type and/or colour is facilitated by rapid access to all components. No tools are required to open or close panels and covers. 200 B 240 1870 1480 1150260 The staggered rotor confi - guration suits more universal and tougher applications. The open rotor is best suited to fi lm and bulky lightweight items such as bottles. Either 2 or 3 fi xed knives can be used. The extra knife enables tougher granulation. A 210...

Abrir la página 8 del catálogoDecision Maker Always the right choice! > An extensive selection of alternatives for 8 dif-ferent machine features gives you the amazing choice of 3840 standard models for the 20 Series of granulators! You can therefore pick the combination of features that best suit your particular application needs when you order a granulator, and rest assured that its the right choice even before the unit is delivered.

Abrir la página 9 del catálogoOne granulator Multiple solutions > Rapid 60 Series size="-1">

Abrir la página 17 del catálogoThe worlds biggest is also >

Abrir la página 18 del catálogoWith a cutterhouse opening of 600 900 mm, the Rapid 60 Series is the worldגs biggest granulator that can be supplied as a soundproofed model. It can recycle a wide variety of plastic waste with equal ease, including pipes, bulky parts like petrol tanks, thick and thin sheets, purgings and diverse containers, bottles, fi lms and profi les. A choice of different models and a wide range of options mean that you can tailor the 60 Series to match your exact needs for numerous applications involving: Central granulationՕ Beside-the-press applications Special above-fl oor or below-fl oor...

Abrir la página 19 del catálogoA number of smart features are built in the Rapid 60 series to make it ideal for a wide range of heavy-duty granulation operations. Increased granulation capacity is achieved by the way plastic waste is fed into the cutter house at a tangential angle. The positive feed that results prevents light-weight hollow products from bouncing on the rotor. The double-scissor cutting action and adjustable blades ensure a fi xed clearance between rotating and fi xed knives thereby main-taining a constant cutting circle, even after knife sharpening. This results in low energy consumption and a high...

Abrir la página 20 del catálogoSpecial solutions for petrol tanks and other large containers. > Granulates diverse pipes and profi les. >

Abrir la página 21 del catálogoReduces large volume, thin plastic material to fl akes. > Ideal for large volume moulded parts. >

Abrir la página 22 del catálogoWhen Rap i d i ntroduced the plast i c granulator to the plast i cs i ndustry i n the 1960s, i ts l i ke had never been seen before . That was the start of what was to become Rap i ds lead i ng technology . Today, w i th the release of Rap i dҒs GranuMATIC l i ne, we are once aga i n p i oneers, launch i ng another truly ded i cated plast i cs recycl i ng mach i ne . Itْs not a granula-tor or a shredder i t֒s GranuMATIC . Unt i l now, shredders have been des i gned for mult i purpose use, but ma i nly for s i ze reduct i on of garbage and wood . The new GranuMATIC > ٙ l i ne has been exclus...

Abrir la página 30 del catálogoCuts the mater i al w i th our PolyCUT technology, i n-stead of shredd i ng . M i n i m i zed mechan i cal stress thanks to slow cutt i ng operat i on . Energy sav i ng . PolyCUT and sequent i al cutt i ng act i on requ i re lower motor power . Rotor cool i ng ava i lable for GranuMATICҙ W i de . Increased capac i ty ach i eved by double kn i fe rows (W i de model) . Mechan i cal stress ab sorb- i ng pneumat i c feed i ng sys-tem, our un i que Flex i PUSH . L i ghtwe i ght, volum i nous goods are effi c i ently fed i nto the rotor by an opt i onal top pusher . Screenless operat i on...

Abrir la página 31 del catálogoTodos los catálogos y folletos técnicos Rapid Granulator

- Rapid OneCUT

5 Páginas

- Rapid Granulator

5 Páginas

- 150 series

8 Páginas

- Rapid 200 Series

5 Páginas

- Rapid Edge trim granulation

2 Páginas

- Rapid GranuMATIC

5 Páginas

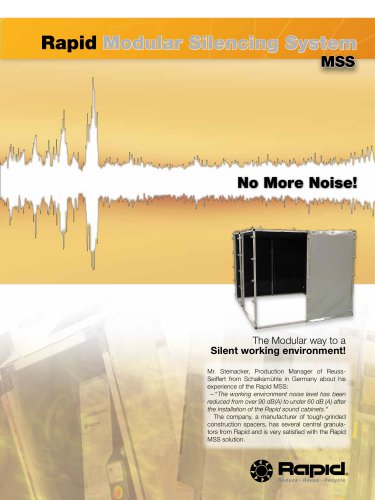

- Rapid Modular Silencing System, MSS

8 Páginas

- Rapid RG Series

5 Páginas

- Rapid 100 Series

2 Páginas

Catálogos archivados

- Rapid 10 series

4 Páginas