Extractos del catálogo

FASCINATIONÍfli PRECISION®

Abrir la página 1 del catálogoContents / Inhaltsverzeichnis Technical data / Technische Daten Art.-Nr. Item no. Gears: Gänge: Rotation speeds (r.p.m.): Drehzahl (U/min): Freqency range Taktfrequenz: Height: Höhe: Magnet (l x w) Magnet Aufstandsfläche (L x B) Weight: Gewicht: Magetic clamping force: Magnetische Haftkraft: Power consumption: Leistungsaufnahme: Cooling supply: Kühlung: Holder: Aufnahme: 1 Plastic tool case / Transportkoffer aus Kunststoff 1 Allen Key / Innensechskantschlüssel 2.5 / 6 1 Safety belt / Sicherungsgurt 1 Drill chuck / Bohrfutter 1,0 - 16,0 mm 1 MT 3 arbor holder / Aufnahmehalter mit MK 3...

Abrir la página 2 del catálogoParts description / Gerätedarstellung Motor Antriebsmotor Allen screws for motor stroke range adjustment Inbusschrauben für Hubbereichseinstellung des Motors Star grip Drehkreuz Clamping lever for clamping the magnet foot Spannhebel für Magnetfuß Control panel Bedienfeld Sicherheitsgutführung Buckle slot of safety belt Magnetic base Magnetfuß Adjusting screw for adjusting the slide Stellschrauben zum justieren des Schlittens Drill spindles MK 3 Bohrspinden MK 3 Push button for "Left-hand rotation" Taster für Linkslauf Depth scale Tiefenskala Rotation speed control Drehzahlregle

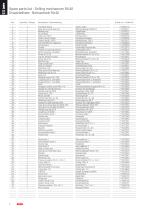

Abrir la página 3 del catálogoSpare parts list - Drilling mechanism RU40 Ersatzteilliste - Bohrantrieb RU40 Quantity / Menge Description / Beschreibung Armature, 230 V Deep groove ball bearing Bearing cap Fan shroud Field coil, 230 V Carbon brush holder Carbon brush, 230 V Anti-interference capacitor Spring discs Screws Printed circuit board 230 V Motor housing, complete Screw 3,9 x 9,5 Cap for motor housing Screw 4,8 x 45 Bearing ring Rotary shaft seal Gear box flange Retaining ring Deep groove ball bearing Retaining ring 32/1,2 Gear box Tapping screw 5,5 x 100 Coupling bolt 2, complete Coupling bolt 1, complete Bush...

Abrir la página 4 del catálogoSpare parts list - Drilling unit RU40 Ersatzteilliste - Ständer RU40 Pos. Quantity / Menge Description / Beschreibung Housing RUKO Front label RUKO Rotary knob RLE Rotary knob pots Set screw Label rotary pots Collar bushing Lock washer Adapter rotary knob Hexagon socket screw Adapter pots Rotary pots Cover rotary pots Typeplate Push button left-/righthand rotation Hexagon socket screw Motor switch Magnet switch Bridge rectifler 400 Volt Cylinder head screw Frame seal Button head screw Typeplate Groove nut Protection plate Wedge plate Wedge Clamp lever Dowel pin Intermediate plate Spring...

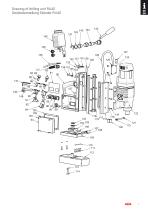

Abrir la página 5 del catálogoDrawing of drilling mechanism RU40 Gerätedarstellung Bohrantrieb RU40

Abrir la página 6 del catálogoDrawing of drilling unit RU40 Drawing of drilling unit RU40 Gerätedarstellung RU40 Gerätedarstellung Ständer Ständer RU40

Abrir la página 7 del catálogoSymbol Term, meaning Use ear protection during operation. Use eye-protection(safety goggle) during operation. Observe the information in the adjacent text! Be absolutely sure to read and understand the enclosed documentaron such as Instruction Manual and the General Safety Instructions. Confirms the conformity of the power tool with the directives of the European Community. Product with basic insulation and exposed (touchable), conductive parts additionally connected to the protective earth conductor. During work with this machine, improper handling and/or poor maintenance result in...

Abrir la página 8 del catálogoThe RUKO magnetic-stand drilling machine RU40 Standard fine adjustment stabilised • Displaceability: ± 10 mm • Pivoting range: ± 30° The RUKO fine adjustment enables repositioning with fixed magnets. Integrated coolant bottle with intelligent coolant supply. Ergonomic handles for easy portability. Better handling due to ergonomic carrying handle. Magnet with 20.000 N clamping force and larger contact surface in models RU40. Turning machine ON and OFF The control panel on your magnetic drilling machine is designed for maximum operating facility and safety. 1 - The ON Switch (GREEN): This...

Abrir la página 9 del catálogoAssembling The magnetic drilling units are supplied with a high powered electromagnet as well as a reclosure preventing device for the drilling mechanism. The magnetic drilling units correspond to protection class I with conductor according to IEC 745. The drilling mechanisms that have been developed according to DIN VDE 0740 and IEC 745-1 are radio screened according to EN 55014 and EN 61000 and are designed for continous operation: It is possible that the sound level exceeds 85 dB (A). In this case special sound protection is necessary for the user. Indications concerning the sound level...

Abrir la página 10 del catálogoBefore putting into operation Plug the cable into a suitable supply. Check the correct voltage! If you are using an extension cable please check if it is suitable for the machine`s rated input power! Attention: For vertical and overhead drilling work it is absolutely necessary to wear the enclosed safety belt. Putting into operation Position the drill bit over the drilling point. Switch the magnetic drilling unit on by pressing the red switch. The magnetic field that is created keeps the drilling unit clamped to the workpiece. Before drilling check if the magnetic drilling unit clamps...

Abrir la página 11 del catálogoAttention: Please read this manual carefully before using the drilling unit The drilling units may only be used according to their determination. The use of the drilling unit as a lifting magnet is dangerous and absolutely inadmissible. The use for another purpose than what is determined endagers people and the machine. Please note also the following safety instructions for electric tools. Attention: Before the use of electric tools please note the following basic safety instructions to avoid electric shock, injuries and fire. Read and follow these instructions before using the electric...

Abrir la página 12 del catálogoGuarantee: The Manufacturer default warranty period is 12 months after date of delivery. Proof is the invoice. Condition is that the machine has been used, maintained and cleaned correctly and that no repairs by others have been made. The guarantee is limited to repairs free of charge or replacements of the damaged parts that are caused by material defects or production faults. Parts that have been damaged by normal wear or repairs made by oneself or others are not subject to this guarantee. This guarantee is only valid if the correct tools, original accessories and spare parts have been...

Abrir la página 13 del catálogoTodos los catálogos y folletos técnicos RUKO GmbH Präzisionswerkzeuge

- RU25

88 Páginas

- A10

60 Páginas

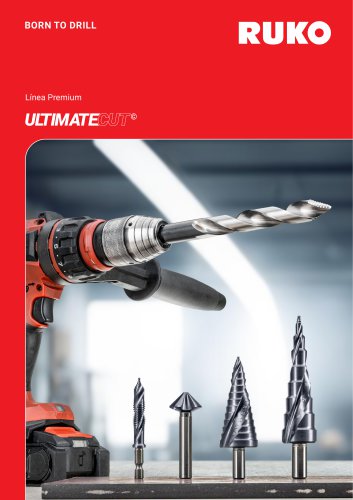

- ULTIMATECUT Premiumlinie

15 Páginas

- CONCRETE DRILLS

9 Páginas

- COOLANTS AND LUBRICANTS

2 Páginas

- SCREW-HOLE PUNCHES

5 Páginas

- DEBURRERS

7 Páginas

- SAWS

29 Páginas

- HOLE SAWS

15 Páginas

- ROTARY BURRS

19 Páginas

- MAGNETIC DRILLING MACHINES

33 Páginas

- CORE DRILLS

19 Páginas

- THREAD REPAIR TOOLS

5 Páginas

- THREAD-CUTTING TOOLS MACHINE TAPS

31 Páginas

- THREAD-CUT TING TOOLS H AND TAPS

21 Páginas

- SINKERS

29 Páginas

- STEP DRILLS

23 Páginas

- TUBE AND SHEET DRILLS

5 Páginas

- SPECIAL DRILLS

5 Páginas

- TWIST DRILLS

49 Páginas

- TOOLS FOR METAL CUTTING

324 Páginas

- RUKO Main catalog

163 Páginas

- Fresa de mecanizado RUKO

- Fresa monobloque RUKO

- Fresa para acero RUKO

- Fresa sujeción

- Fresa para metal RUKO

- Broca monobloque RUKO

- Fresa de cono cilíndrico

- Fresa con plaquitas sustituibles

- Hoja de sierra

- Fresa para hierro fundido RUKO

- Fresa con recubrimiento

- Fresa para corte RUKO

- Herramienta de taladrado multiusos

- Fresa carburo sólido

- Fresa frontal hemisférica

- Broca de carburo de tungsteno

- Fresa de alta eficacia RUKO

- Fresa para aluminio RUKO

- Fresa para acero inoxidable

- Fresa borde de corte RUKO